Are you thinking about a closed trailer to move your collector car to events? The first question to ask is: Do you have a vehicle...

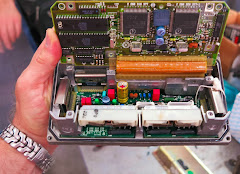

Bentley archives

Land Rovers

What makes up the annual upkeep costs for a vintage Bentley or Rolls Royce? When people ask me what it will cost to k...

Your check engine light comes on, but the engine in your car seems to run fine. What’s the worst it can be, you ask? That’s never a goo...