It’s late November, time for collector cars to be put in storage all over New England. These are some thoughts from my 25 years doing thi...

Bentley archives

Land Rovers

How long do tires last? If you have a collectible car, the tires may look new, yet be fallin...

In my last story I described replacement of the backup batteries in the Rolls-Bentley alarm controller under the dash. This story sort o...

This past weekend we had unprecedented damage from an early snowstorm. Trees were down across all the roads in town, and many took powerl...

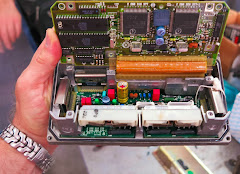

I get quite a few calls asking about battery replacement in the security and memory seat modules of Rolls Royce and Bentley cars. In this a...