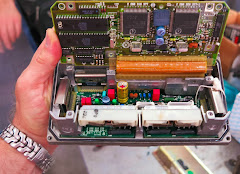

We are seeing a disturbing trend with many high end cars built in the 1980s and 1990s. Their auxiliary control modules are failing, and rep...

Bentley archives

Land Rovers

A few weeks ago, I had a strange and curious experience with a Range Rover. It started with a simple warning light, and the usual reques...

Sports fans know Springfield as the home of the Basketball Hall of Fame. Each year, a new class of players and coaches is inducted in a nat...

Meet Dave Tassinari, my neighbor here on Page Boulevard. Seven years ago we sold Dave a tired old 928. "I'm going to take it apart...

Note: This story was written a few years ago, but it's even more true today. Robison Service is building 4.0, 4.6, and oversize Land R...

It’s spring in New England. Now that the snow is gone, the Rolls Royces and Bentleys are coming out of the woodwork. I’d like you to meet o...

This week we are wrapping up some modifications to an ex-NATO Defender 90. If you’ve looked inside one of these Army truck you know they a...

I thought I'd change direction for a moment and show you one of the machines our company ( J E Robison Service )builds. We're known ...

Look Me In The Eye: A summary of my TMS posts

Look Me In The Eye: Brain Plasticity and how it affects us

Look Me In The Eye: A return to the TMS lab

Look Me In The Eye: Brain Plasticity and TMS

Our shop has been featured on the Land Rover Geeks website as a world-class Land Rover repair facility: Land Rover Repair Shop Directory Her...

I grew up thinking of oil changes as inexpensive, quick services. Yet the simplest of services on a late model Mercedes or BMW seems to cos...

Do you have a VW diesel that used to be powerful and now it's weak? Did your fuel economy sink from 50 to 40 or even less? The problem...

Most high end cars have two parts to their keys. There is a mechanical key blade that physically unlocks a mechanism, and there is an in...

To reset the service reminder on Land Rover This tip comes from Geoff Kelly in the UK . . . 1. Insert key in ignition. 2. Press AND HOLD the...